Special Design for Automatic Gummy Candy Making Machine - DGS Series Automatic Plastic Ampoule Forming Filling Sealing Machine – Cmore

Special Design for Automatic Gummy Candy Making Machine - DGS Series Automatic Plastic Ampoule Forming Filling Sealing Machine – Cmore Detail:

|

Model |

DGS-118 |

DGS-240 |

|

Max Forming Depth |

12mm |

12mm |

|

Cutting Frequency |

0-25 times/min |

|

|

Packing Material |

PVC/PE/PET(0.2-0.4)×120mm |

PVC/PE/PET(0.2-0.4)×240mm |

|

Packing Roll |

Two rolls |

One roll |

|

Filling Volume |

1-50ml |

1-100ml |

|

Filling Head |

5 heads |

|

|

Total Power |

7kw |

|

|

Voltage |

220v-380v/50Hz |

|

|

Weight |

900Kg |

1000Kg |

|

Outer Size(L*W*H) |

2300×850×1500(mm) |

3380×950×1800(mm) |

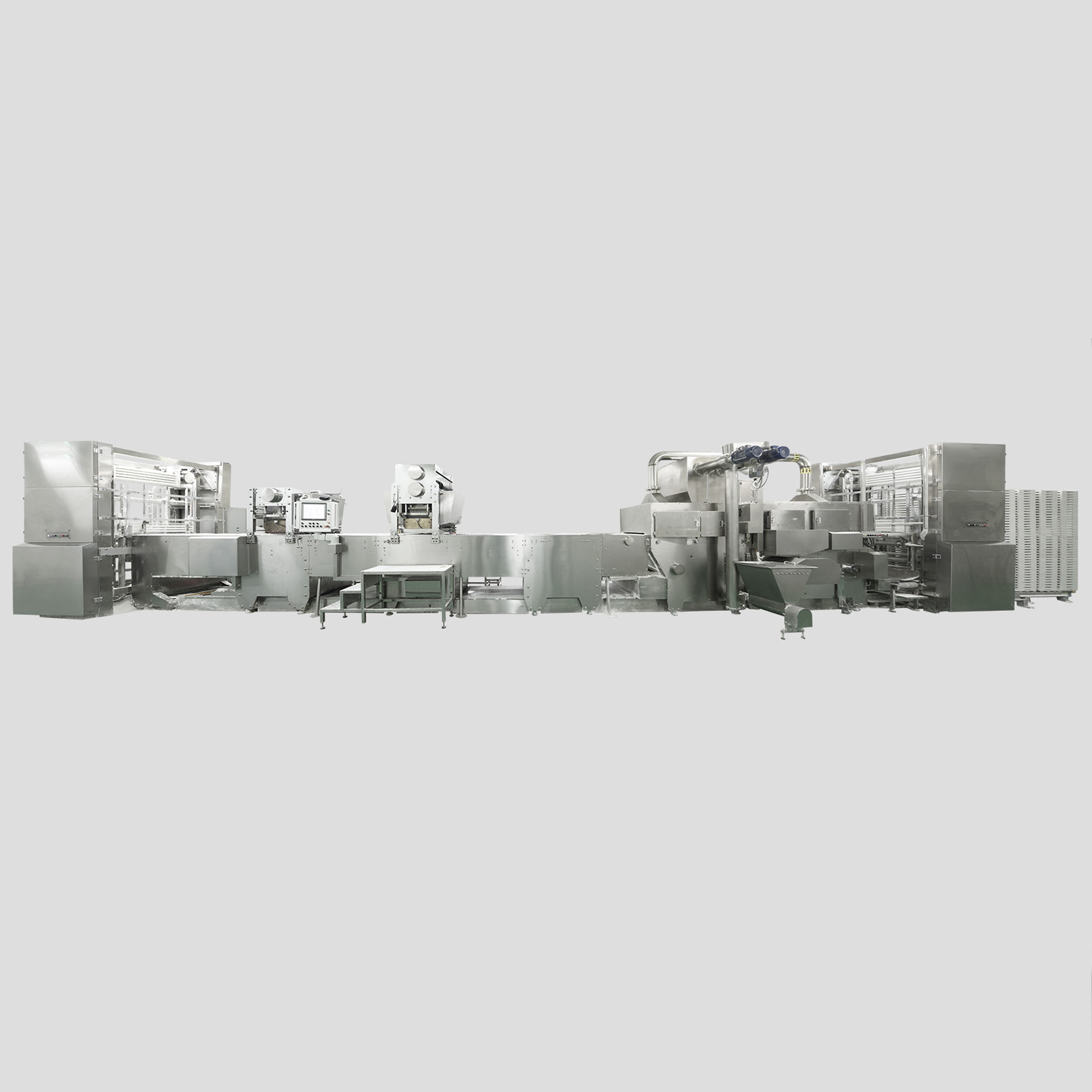

DGS-240 automatic oral liquid plastic bottle forming and filling machine includes a frame, a feeding device and a control system.It has a compact structure, which makes it automatic operation, low manufacturing cost and reliability production efficiency.This machine is suitable for the unit dose of medicine, drinks, dairy products, health products, food, cosmetics, perfume, agricultural medicine, fruit purees, etc.It can finish the following working process including the following:Packing film unwinding–folding–bottle/ampoule forming–product filling–sealing–final product output. We can also add the extra printing and letter or logo engraving function on the machine.

1. High speed and high precision high-end motion controller.

2. Stepless frequency control of motor speed control.

3. Servo motor control tensile membrane device.

4. Automatic discharge volume, a roll of film cutting, can be folded in half.

5. There are positive and negative photoelectric pattern of version of the function. Products elegant, meet high standards of packaging requirements.

6. Using electronic peristaltic pump device. And mechanical pump piston pump control. Filling accuracy is correct.

7. Filling does not drip, no bubble, no overflow.

8. At the bottom of the bottle is flat, could stand.

9. Automatic stop when each door opening.

Product detail pictures:

Related Product Guide:

Every member from our high efficiency sales team values customers' needs and business communication for Special Design for Automatic Gummy Candy Making Machine - DGS Series Automatic Plastic Ampoule Forming Filling Sealing Machine – Cmore, The product will supply to all over the world, such as: Romania, Sweden, Frankfurt, We've established long-term, stable and good business relationships with many manufacturers and wholesalers around the world. Currently, we've been looking forward to even greater cooperation with overseas customers based on mutual benefits. You should feel free to contact us for more details.

We are really happy to find such a manufacturer that ensuring product quality at the same time the price is very cheap.