Rapid Delivery for Automatic Bottle Cleaning Machine - Model DSB-400H High Speed Double Line Four Sides Sealing Automatic Packing Machine – Cmore

Rapid Delivery for Automatic Bottle Cleaning Machine - Model DSB-400H High Speed Double Line Four Sides Sealing Automatic Packing Machine – Cmore Detail:

|

Items |

Parameters |

|

Model |

DSB-400H |

|

Production capacity |

150-300 bags/min |

|

Packing size |

L:60-150 mm W:60-200 mm H:1-6 mm |

|

Air compressed |

0.3m3/min |

|

Air pressure |

0.5-0.7Mpa |

|

Rated voltage |

AC380V 50Hz |

|

Total power |

23.5kw |

|

Weight |

500Kg |

|

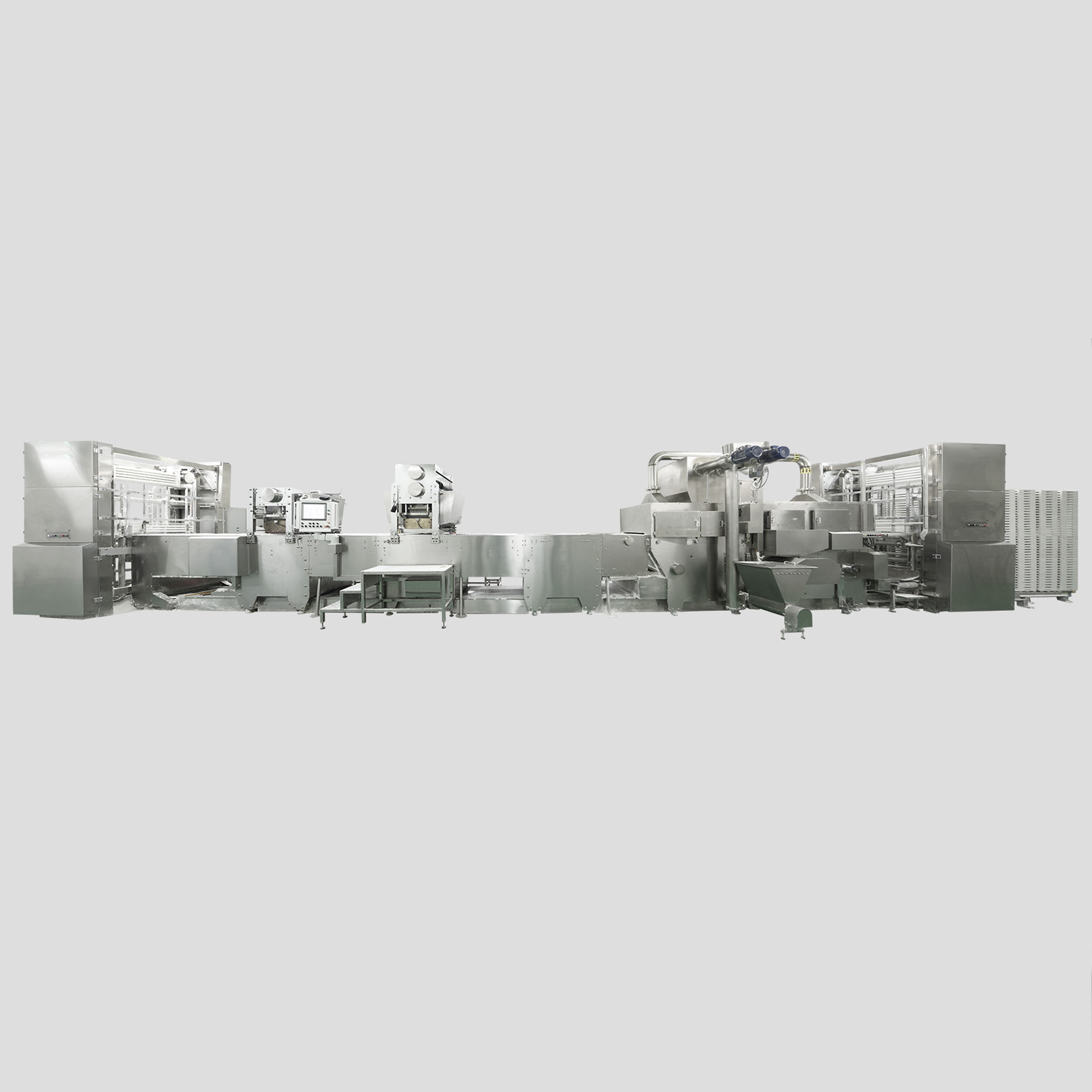

Overall dimension |

6500×2260×2155 mm(L×W×H) |

The whole machine adopts the man-machine interface, PLC programmable control, the transmission parts are using servo motor independent control, total used twelve servo motors drive. High speed turntable multi pieces feeding, double servo feeding, servo unwinding, package material of upper and lower remark detection, batch printing, reciprocating sealing, easy opening, rolling and cutting waste edge, cut off the waste and collecting device, hob cutting and finished products delivery mechanism etc. The whole machine runs smoothly, the product specification is convenient to replace, and the parameters one button set. The machine superior performance, high degree of automation, is the preferred equipment for automatic packaging plaster.

A. Touch screen control, simple operation.

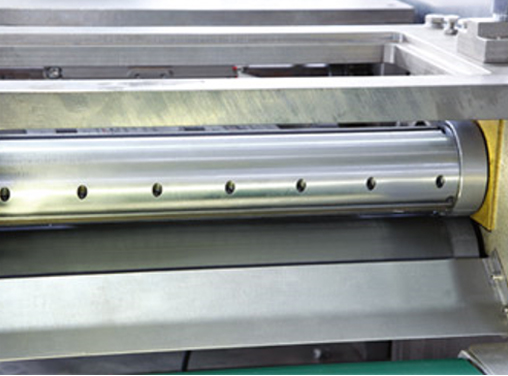

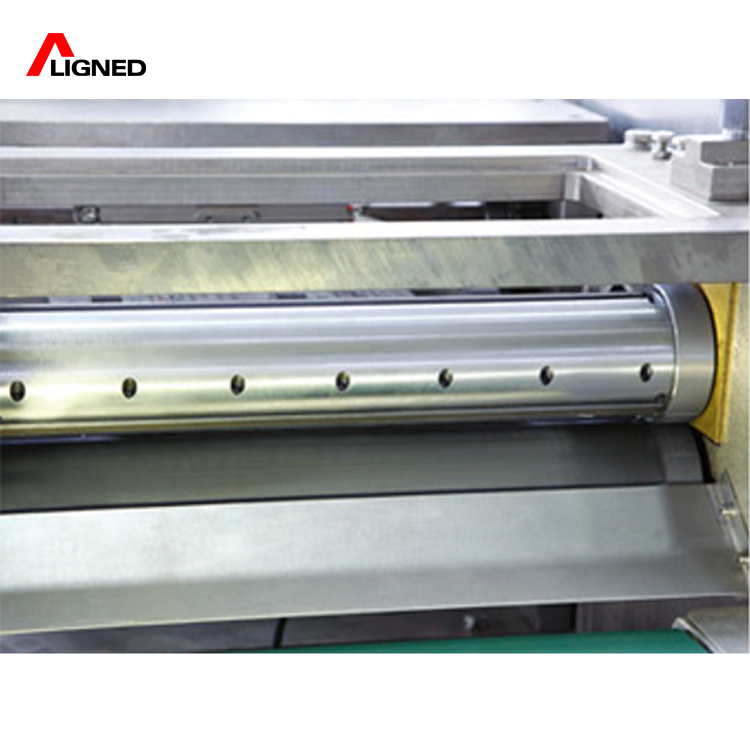

B. Reciprocating heat sealing, the standard paste size can be heat sealed 10 bags at a time, the sealing is smooth, firm and beautiful.

C. The packaging film tape joint is automatically detected and rejected.

D. The code machine misses and automatically rejects.

E. Missing pieces will automatically detect rejection.

F. No film will alarm shutdown.

G. It can be applied to a variety of specifications, and can be equipped with 1-5 pieces of automatic feeding.

H. Ethernet remote control. Can modify the program.

Product detail pictures:

Related Product Guide:

Our company has been concentrating on brand strategy. Customers' pleasure is our greatest advertising. We also source OEM service for Rapid Delivery for Automatic Bottle Cleaning Machine - Model DSB-400H High Speed Double Line Four Sides Sealing Automatic Packing Machine – Cmore, The product will supply to all over the world, such as: Sevilla, Cologne, Iran, Why we can do these? Because: A, We are honest and reliable. Our items have high quality, attractive price, sufficient supply capacity and perfect service. B, Our geographical position has a big advantage . C, Various types: Welcome your inquiry, It might be highly appreciated.

The accounts manager made a detailed introduction about the product, so that we have a comprehensive understanding of the product, and ultimately we decided to cooperate.