Online Exporter Automatic Gummy Candy Production Line - Gummy Production LINE – Cmore

Online Exporter Automatic Gummy Candy Production Line - Gummy Production LINE – Cmore Detail:

| Production capacity | 8000-20000 kg/8 hours (depending on the shape of the candy produced) | |||

| Power consumption | Power specification | 380v 50hz | ||

| Pouring Line | 40kw Powder Processing | 85kw Other Auxiliary Equipment | 11kw Cooking System | 51kw |

| Steam volume | (Steam pressure is greater than 0.8MPa) Water consumption | It depends on the production situation | ||

| Compressed air | 7-8m3/min (compressed air pressure 0.6MPa) | |||

| 2- 4′C cold water | 0.35m3/min | |||

| The ambient temperature of equipment T is 22- 25C, and the humidity is below 55% | ||||

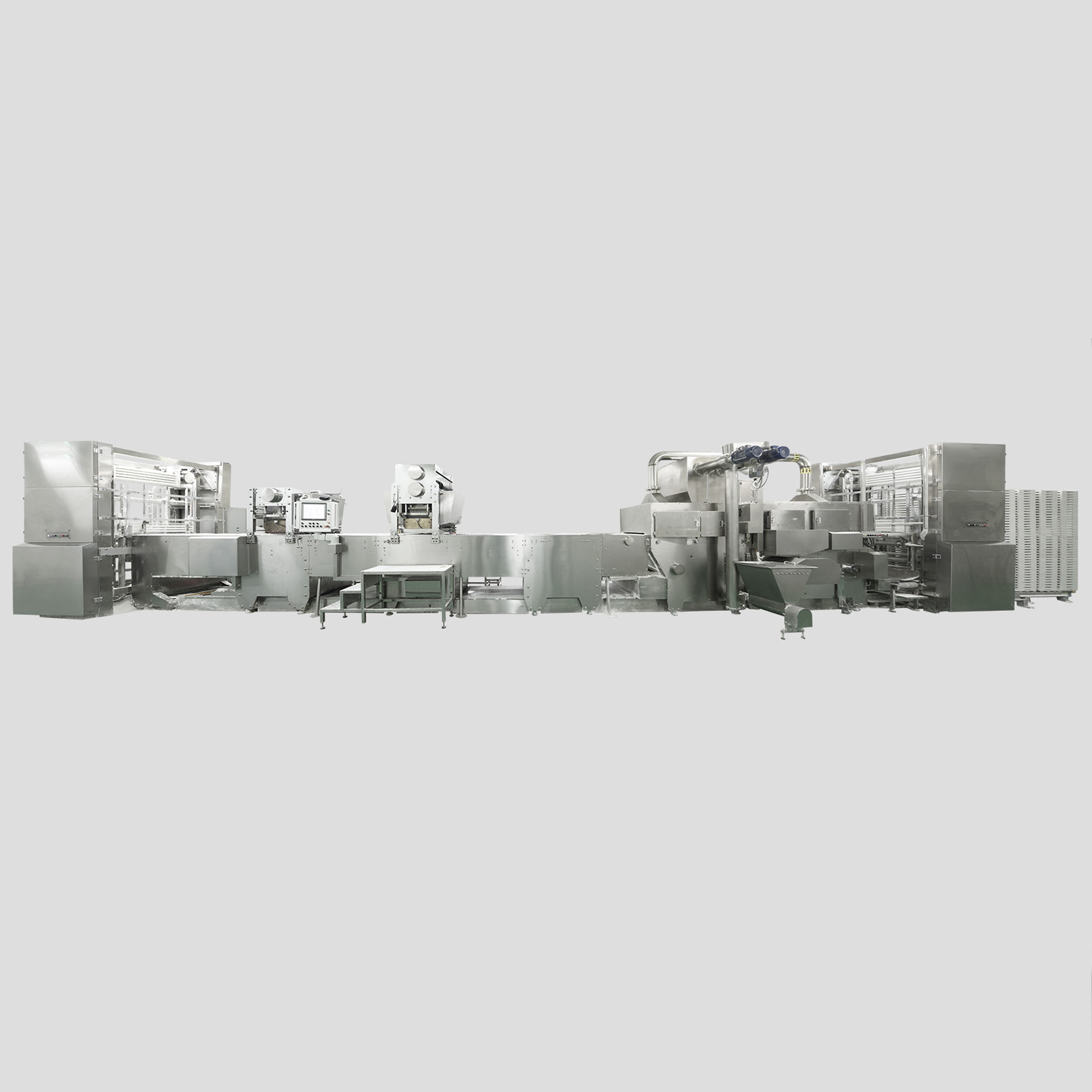

This production line is a special advanced equipment for the production of starch mold soft candy. The machine has a high degree of automation, easy operation, reliable operation and stable speed. The whole line includes sugar boiling system, pouring system, finished product conveying system, powder processing and powder recovery system. According to customer requirements, the candy shape is professionally arranged and designed, so that users can get the best production effect and maximum output. This machine can produce starch gummies, gelatin and center-filled gummies, pectin gummies, marshmallows and marshmallows. This equipment is an advanced candy production equipment integrating all kinds of soft candies, and has won the trust of customers with good quality and high output.

1. LIFTING COOLER:

The machine consists of two systems: a thermal dryer system and a cooling system. The heating drying system can control the humidity of starch below 7%, and the cooling system can effectively reduce the starch temperature below 32℃. Complete processing and recovery of starch can be achieved by heating drying system and cooling system.

2. BOIL SUGAR SYSTEM:

The entire sugar boiling cycle of continuous vacuum boiling takes only 4 minutes, thus ending the sugar boiling process as quickly as possible.

3. AUXILIARY MACHINERY:

A. Front of conveyor: conveying and preliminary cleaning of starch

B. Back of conveyor belt: conveying and cleaning starch twice

C. Candy wetting conveying: make finished jelly candies convenient for icing by steam wetting

D. Sugar Coating Machine: Sugar that coats finished jelly candies

E. Oiler: Oil the finished jelly candy

Product detail pictures:

Related Product Guide:

we are able to provide good quality items, aggressive rate and best shopper assistance. Our destination is "You come here with difficulty and we provide you with a smile to take away" for Online Exporter Automatic Gummy Candy Production Line - Gummy Production LINE – Cmore, The product will supply to all over the world, such as: Kuala Lumpur, London, Sao Paulo, Business philosophy: Take the customer as the Center, take the quality as the life, integrity, responsibility, focus, innovation.We will provide professional, quality in return for the trust of customers, with most major global suppliers,all of our employees will work together and move forward together.

Problems can be quickly and effectively resolved, it is worth to be trust and working together.