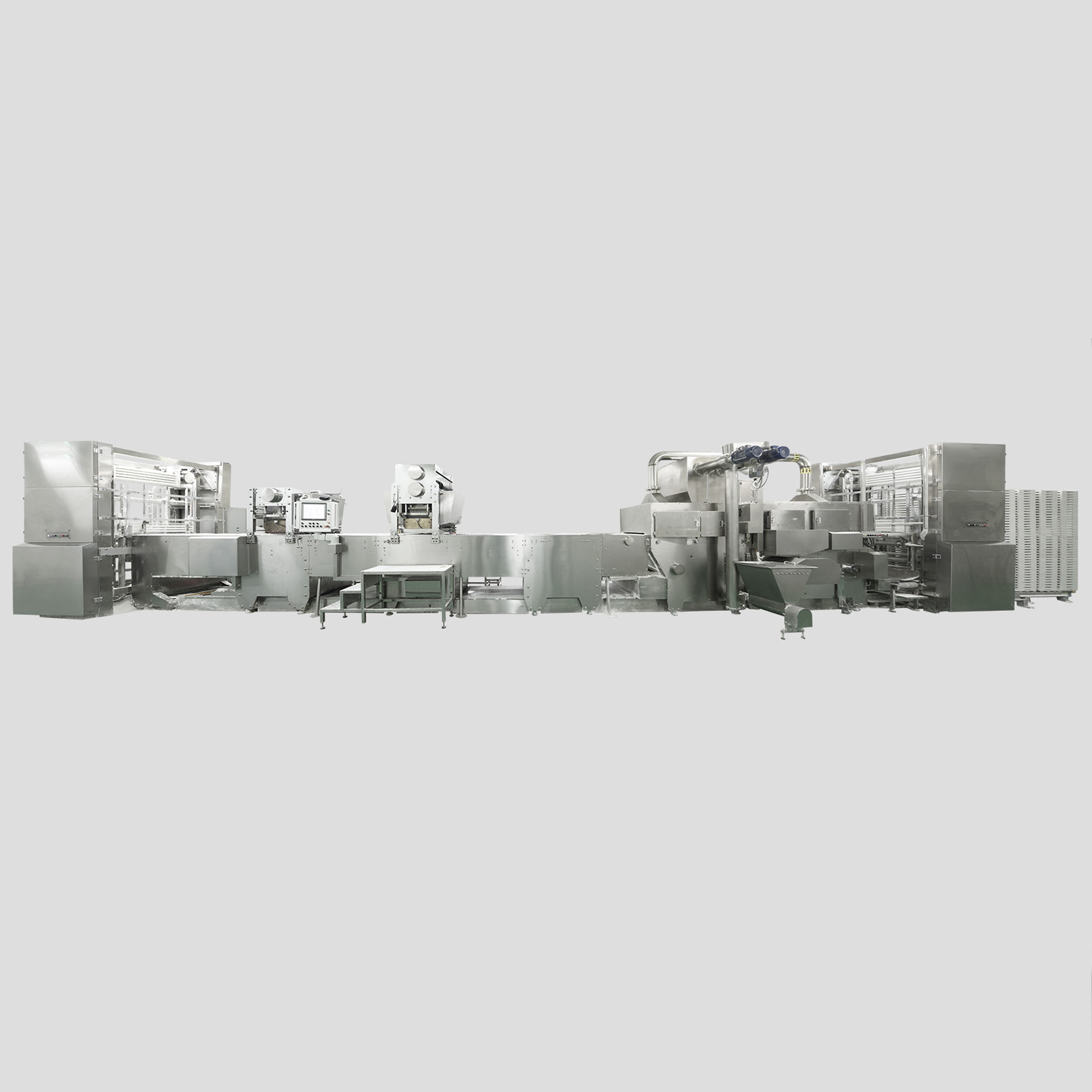

Factory wholesale Candy Production Line - The Leading Solution For The Fully Automatic Filling And Capping Line (5L-25L) – Cmore

Factory wholesale Candy Production Line - The Leading Solution For The Fully Automatic Filling And Capping Line (5L-25L) – Cmore Detail:

| Technical Parameter | |||||

| Head | Capacity (bottle/h) | Compatible Capacity (L) | Total Power (KW) | Total Size (L*W*H) mm | Voltage (V) |

| 4 | 600-800 | 5-25 | About3-4 | 8000x1500x2100 | 380V |

| 6 | 800-1000 | 10000x1500x2100 | |||

| 8 | 1100-1300 | About4-5 | 12000x1500x2100 | ||

| 10 | 1300-1500 | 14000x1500x2100 | |||

| 12 | 1500-1800 | About5-7 | 16000x1500x2100 | ||

Note: The above quantitative error:±0.3-0.5% ml. The above output refers to 5L. The nature of the filling medium is close to that of water, and there is a±10% fluctuation in the speed of different materials.

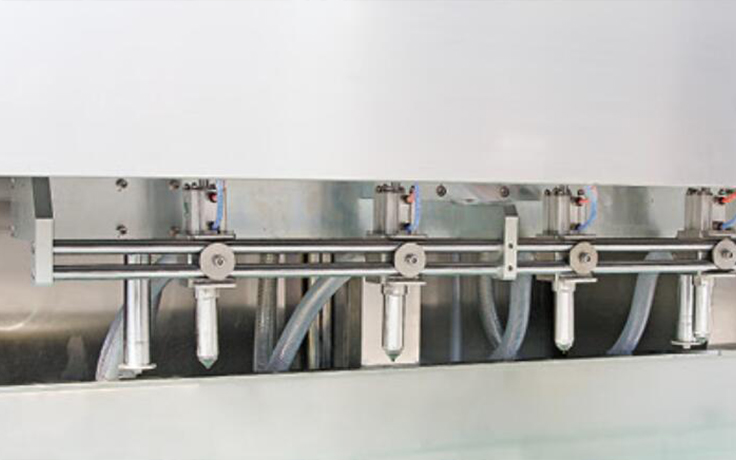

1.2‰ high- precision Roots flowmeter with high-precision pulse encoder for quantification. Filling accuracy and reliability;

1. The filling head is equipped with an independent vacuum sucking device, and the filling nozzle is uniformly recovered;without dripping, double-speed filling, more stable and no foaming, and more accurate filling.

2. Fast and slow two-speed filling, no bubbling during filling and no spillage of materials;

3. The equipment is compatible with a variety of bottle types and can be used for multiple purposes. Cost- effective equipment.

5. The equipment is simple to operate, complete safety protection measures, and fully protect the safety of users.

6. Food grade stainless steel conveying pipe is safe and sanitary without plasticizer ingredients.

7. It adopts self-configured 2.5kw, 30t/h high-power pipeline pump, automatic suction, and the feeding end is equipped with a bag filter. The whole machine can be used for 10000 hours without consumables.

8. The electrical accessories are all first-line brands such as Germany’s Siemens and France’s Schneider to ensure stable operation and durability of the equipment.

Product detail pictures:

Related Product Guide:

Attaining consumer satisfaction is our company's purpose without end. We will make wonderful endeavours to produce new and top-quality merchandise, satisfy your exclusive requirements and supply you with pre-sale, on-sale and after-sale services for Factory wholesale Candy Production Line - The Leading Solution For The Fully Automatic Filling And Capping Line (5L-25L) – Cmore, The product will supply to all over the world, such as: Uruguay, Rwanda, Zimbabwe, Honest to every customers are our requested! First-class serve, best quality, best price and fastest delivery date is our advantage! Give every customers good serve is our tenet! This makes our company get the favour of customers and support! Welcome all over the world customers send us enquiry and looking forward your good co-operation !Make sure you your inquiry for more details or request for dealership in selected regions.

High Quality, High Efficiency, Creative and Integrity, worth having long-term cooperation! Looking forward to the future cooperation!