1. The emulsifying head can be customized according to the size of the material particles to meet different needs, and the minimum can reach nanometers and microns.

2. After the emulsification pot lid is raised, the safety device is activated: the power system of the stirring device will not be started. To avoid causing personal injury.

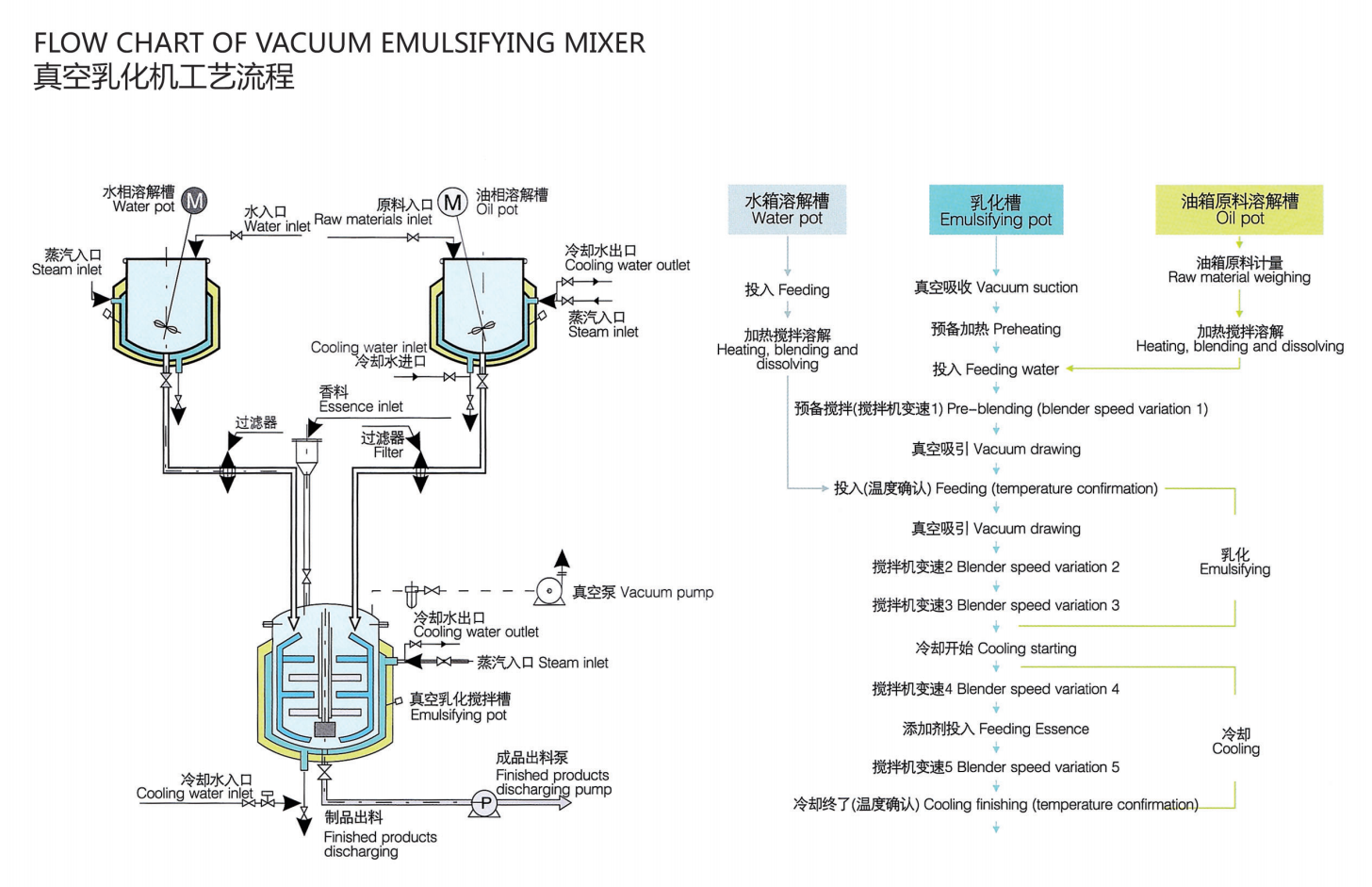

3. The vacuum emulsifier uses a three-stage stirring system. The entire emulsification process is in a vacuum environment, which can not only eliminate the foam generated during the emulsification process, but also avoid unnecessary pollution.

4. PLC control, easy to operate, freely adjust temperature, time, etc., and automatically record historical temperature

5. The vacuum emulsifier is equipped with a CIP cleaning system, making cleaning simple and effective.

6. The modular design of the mixing shaft can be freely assembled and easy to maintain and clean.