2022 Latest Design Fully Automatic Filling And Capping Line - TF-80 Tube Filling And Sealing Machine – Cmore

2022 Latest Design Fully Automatic Filling And Capping Line - TF-80 Tube Filling And Sealing Machine – Cmore Detail:

| Model | TF-80A | TF-80 |

| Hose Material | Metal tube, Aluminum tube | Plastic pipe, Composite pipe |

| Tube Diameter | Φ10- Φ32 | Φ10- Φ60 |

| Tube Length | 60-200(Customizable) | 60-200 (Customizable) |

| Capacity | 5-250ml/tubes/ Adjustable | 5-250ml/tubes/ Adjustable |

| Filling Accuracy | ≤±0.5% | ≤±0.5% |

| Speed(tubes/h) | 60-80 | 60-80 |

| Compressed Air | 0.55-0.65mpa | 0.55-0.65mpa |

| Power | 1.5kw(380V 50Hz) | 1.5kw(380V 50Hz) |

| Heat sealing power | 3.3kw | |

| Dimension(L*W*H/mm) | 2424×1000 ×2020 | 2424×1000×2020 |

| Weight(kgs) | 1500 | 1500 |

1. Reasonable structural design. This machine fully embodies the advanced, reliable and rational design concept required by GMP for pharmaceutical equipment, and reduces the human factors in the use process. The automatic feeding of the tube, automatic positioning of the tube color mark, filling, end-sealing, batch numbering, and exit of the finished product, adopt the linkage design, and all actions are completed synchronously.

2. Fully meet the requirements of the material for the filling process:

a. The machine is compact, the time from filling to end sealing is short, and it can complete complex end sealing forms.

b. To ensure that the filling process is not polluted, the material of the contact part of the machine and the material is all made of 316L stainless steel, and the contact surface is fully polished.

c. High filling precision, the machine adopts reliable piston type quantitative filling valve, the filling volume adjustment is convenient and reliable, and the filling precision is high.

d. The filling components are easy to disassemble, and the barrel valve body, piston injection head, etc. can be quickly disassembled, which is easy to clean, disinfect and sterilize.

e. When filling, the injection nozzle can extend into the tube, which can ensure effective injection and prevent the material from sticking to the wall of the aluminum tube and affecting the sealing.

f. An air blow-off device is installed, and the injection head adopts a combined blow-off and cut-off injection method to prevent the viscous material from pulling out the filament, which affects the sealing and filling volume.

3. Fully enclosed ball bearings are used in the operation part of the manipulator, and linear bearings and self-lubricating systems are used on the upper and lower sliding shafts of the machine table to avoid pollution.

4. The automatic filling and sealing machine adopts the frequency conversion stepless speed regulation system, and the working operation is controlled by coordinated linkage, which can obtain a higher production speed. The pneumatic control system is equipped with a precision filter and maintains a certain stable pressure.

5. Beautiful appearance, easy to clean. The machine is beautiful in appearance, polished and refined by stainless steel, compact in structure, easy to clean without dead ends, and fully complies with the GMP requirements of pharmaceutical production.

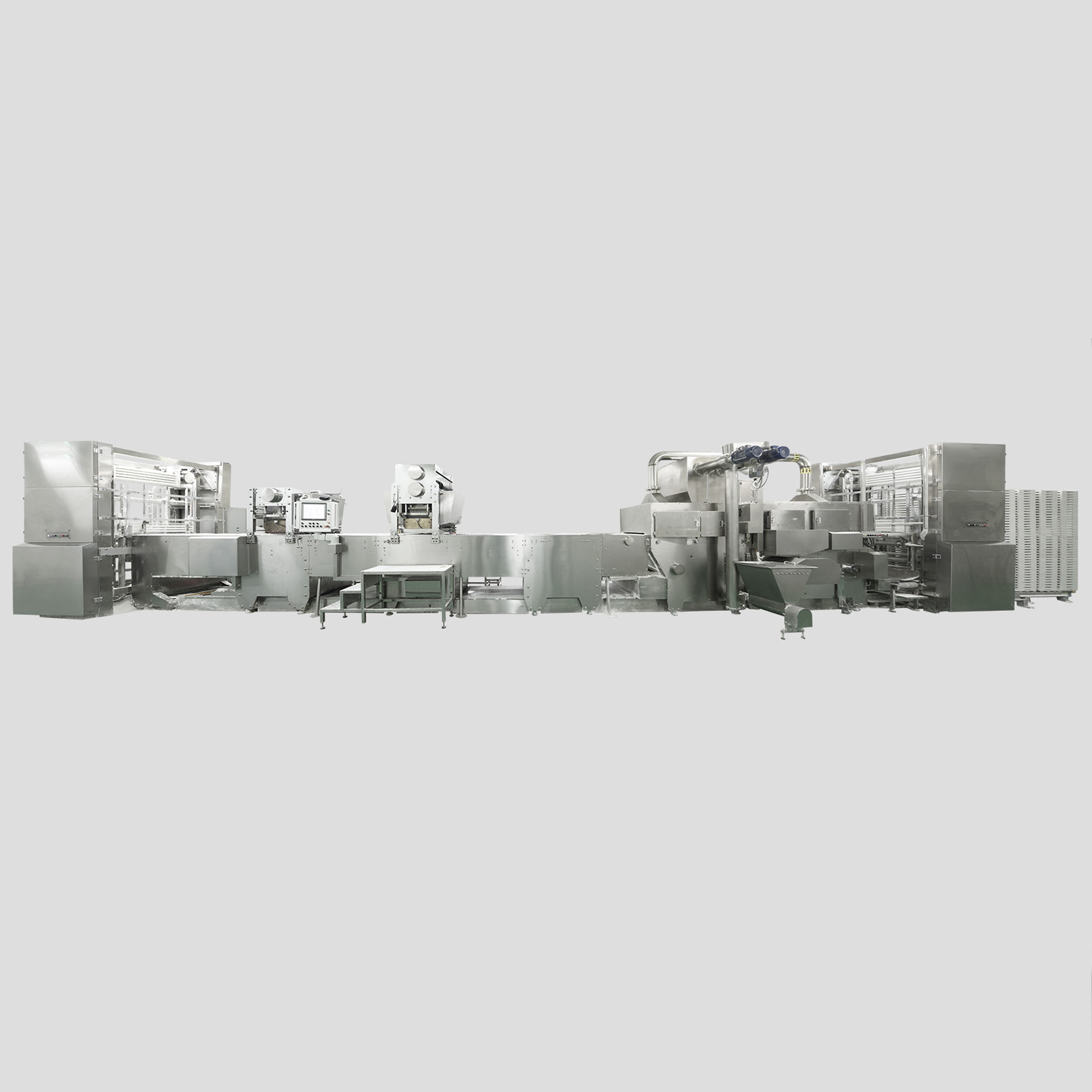

Product detail pictures:

Related Product Guide:

We can easily usually fulfill our respected customers with our very good top quality, very good price tag and excellent support due to we have been more expert and much more hard-working and do it in cost-effective way for 2022 Latest Design Fully Automatic Filling And Capping Line - TF-80 Tube Filling And Sealing Machine – Cmore, The product will supply to all over the world, such as: Qatar, Mali, Plymouth, Due to our dedication, our products are well known throughout the world and our export volume continuously grows every year. We will continue to strive for excellence by providing high quality products that will exceed the expectation of our customers.

In our cooperated wholesalers, this company has the best quality and reasonable price, they are our first choice.